The VIVUS COMPO system is available in 3 different sizes with shredder and remote control

The choice of the right model is determined by the quantity of waste generated daily

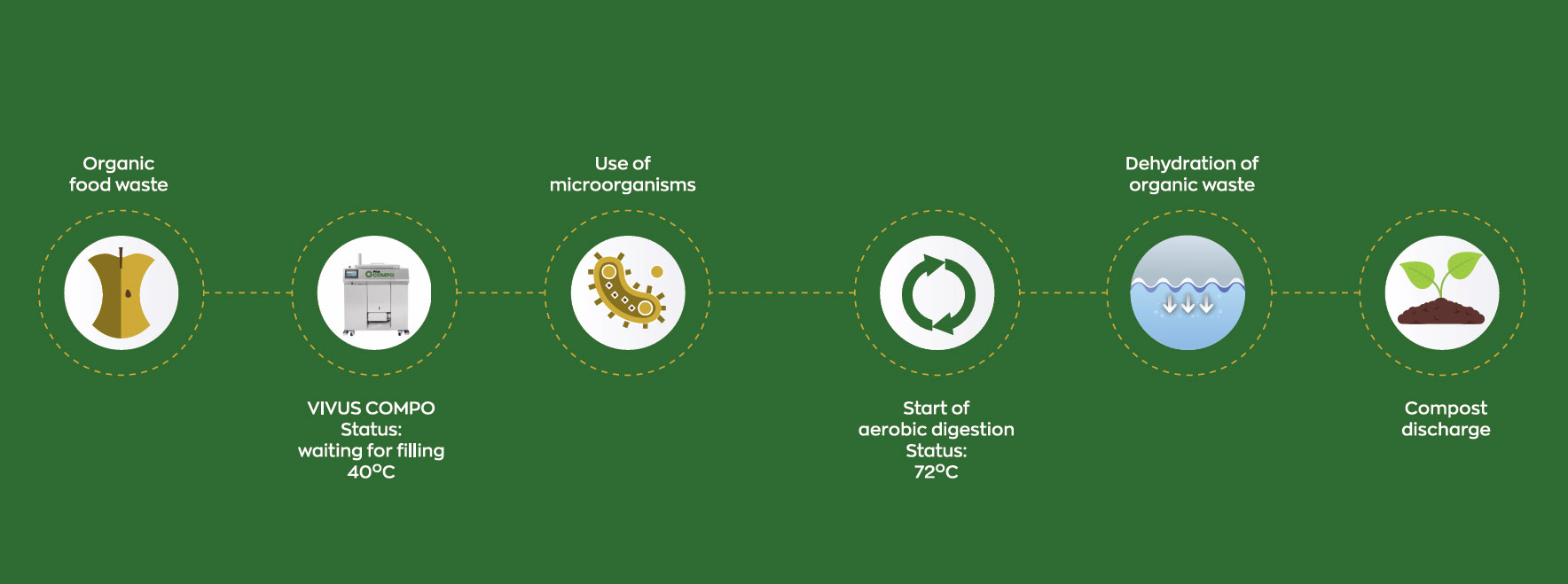

A natural decomposition process—just much faster

Aerobic Digestion – Dehydrator (AD) is a transformation technology that reshapes our approach to both waste management and renewable energy sources.

This is a biological thermal process in which microorganisms break down organic material with the help of high temperatures. This process converts waste into a digested residue in the form of soil, providing numerous environmental and economic benefits.

The Vivus Compo replicates the natural process of decomposition, reducing the time from 45+ days to 8–14 hours.

Μοντέλα VCOMPO

APPLICATIONS: Small sized spaces

FEATURES

- Operation Conditions

- Room Temperature > 18° C

- Room Humidity < 60 %

- Food Input > 17° C

- Acid Food < 10 % of total weight

- Heavy-duty machine, stainless steel construction

- Heavy-duty Shredder for food component

- High efficient M.O. designed by WORLD VIVUS

- Continuous Filling operation until the batch is full.

- The digester has been specifically engineered for efficient use automatically, user-friendly interface

- Data analysis system and remote control by Earth Vivus cloud platform

SPECIFICATIONS

Material

Stainless steel

Weight

300 Kgr

Dimensions

1000mm (L)

950mm (D)

1150mm (H)

SHREDDER

350mm x 250mm, 36 blades, 1,5 kw motor variable speed by inverter

Power Requirements

230V / 25A

Power Consumption

0,6 kwh per kilo waste

Daily Processing Capacity

From 40 Kgr up to 80 Kgr

Required Supplies

M.O. Vivus thermofilic

Installation Requirements

Electrical – Dedicated 230V / 25amp.

Internet cable connection

Wifi (optional) – 4G (optional)

Exhaust to outside

Smell filter (optional)

output

75 – 95% volume and weight reduction depending on food moisture content

APPLICATIONS: Medium sized spaces

FEATURES

- Operation Conditions

- Room Temperature > 18° C

- Room Humidity < 60 %

- Food Input > 17° C

- Acid Food < 10 % of total weight

- Heavy-duty machine, stainless steel construction

- Heavy-duty Shredder for food component

- High efficient M.O. designed by WORLD VIVUS

- Continuous Filling operation until the batch is full.

- The digester has been specifically engineered for efficient use automatically, user-friendly interface

- Data analysis system and remote control by Earth Vivus cloud platform

SPECIFICATIONS

Material

Stainless steel

Weight

410 Kgr

Dimensions

1400mm (L)

950mm (D)

1150mm (H)

SHREDDER

350mm x 250mm, 36 blades, 1,5 kw motor variable speed by inverter

Power Requirements

230V / 32A

Power Consumption

0,55 kwh per kilo waste

Daily Processing Capacity

From 100 Kgr up to 200 Kgr

Required Supplies

M.O. Vivus thermofilic

Installation Requirements

Electrical – Dedicated 230V / 32amp.

Internet cable connection

Wifi (optional) – 4G (optional)

Exhaust to outside

Smell filter (optional)

output

75 – 95% volume and weight reduction depending on food moisture content

APPLICATIONS: Medium & Large sized spaces

FEATURES

- Operation Conditions

- Room Temperature > 18° C

- Room Humidity < 60 %

- Food Input > 17° C

- Acid Food < 10 % of total weight

- Heavy-duty machine, stainless steel construction

- Heavy-duty Shredder for food component

- High efficient M.O. designed by WORLD VIVUS

- Continuous Filling operation until the batch is full.

- The digester has been specifically engineered for efficient use automatically, user-friendly interface

- Data analysis system and remote control by Earth Vivus cloud platform

SPECIFICATIONS

Material

Stainless steel

Weight

520 Kgr

Dimensions

1870mm (L)

950mm (D)

1150mm (H)

SHREDDER

350mm x 250mm, 36 blades, 1,5 kw motor variable speed by inverter

Power Requirements

230V / 32A

Power Consumption

0,5 kwh per kilo waste

Daily Processing Capacity

From 150 Kgr up to 300 Kgr

Required Supplies

M.O. Vivus thermofilic

Installation Requirements

Electrical – Dedicated 230V / 32amp.

Internet cable connection

Wifi (optional) – 4G (optional)

Exhaust to outside

Smell filter (optional)

output

75 – 95% volume and weight reduction depending on food moisture content